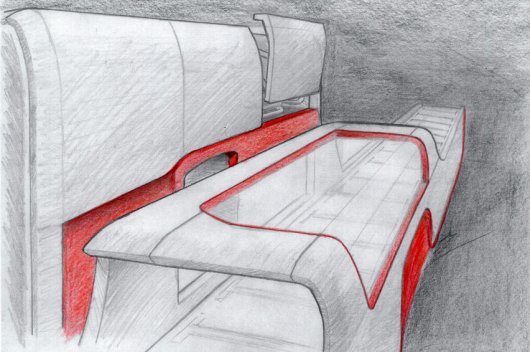

Sheet metal systems

Custom sheet metal systems from the first design draft to the finished product – adapted specifically to customer requirements:

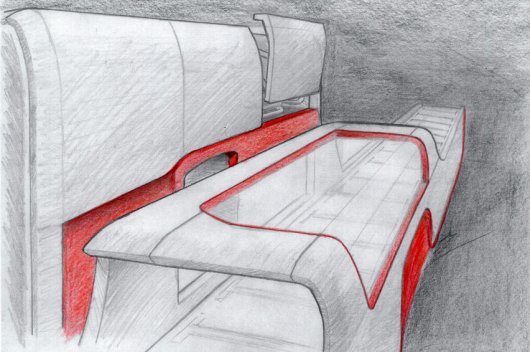

- In a first step, the wishes of the customer are converted using our design ideas and practical expertise into a convincing and production-ready design.

- The constructive implementation of the design draft, as well as all other specifications and conditions, tailored to the special technological opportunities of the respective production partner, are the focus of the second project phase.

- The next step of this process is the manufacture of the prototype, such as the machine housing, which is performed at the production partner's site – from the laser cutting to the finished painted assembly unit.

- In order to present the product in the quality you expect, our designers coordinate all interfaces on site throughout the entire process down to the final assembly to present errors and to save time.

Our portfolio encompasses:

- Individual components / assemblies made of sheet metal

- Optimized basic frame systems

- Machine housings

- Functional assemblies; e.g., podiums, stairs, work platforms

- Booths for assembly workplaces

- Stainless steel units

- Refrigeration units for stationary and mobile applications

- Built-in appliances for shop fitting and industrial kitchens; e.g., cooling troughs